Why are constant

temperature conditions

necessary?

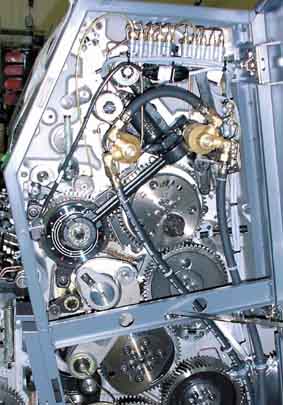

Printing machines, print rollers and printing inks are all subject to

continual temperature effects. This means varying printing results, and could also lead to poor printing quality. Different temperatures within the machine also result in registration and trapping problems, dot-gain variances, uneven drying and picking. In large-format offset printing and in roll offset printing, inking system temperature control is used as a standard feature in order to guarantee a constant temperature throughout the whole system. The precision of the digital pre-press stage and the optimum printing quality can only be ensured by means of the constant temperature that can be achieved with the use of inking system temperature control. The investment is well worth while: if you are printing using water, you can reduce your IPA costs considerably – making waterless offset printing a thing of the past. You can determine at any time what temperature to use for printing by means of freely

selectable temperature settings.